Roll Wrapping Process

Roll Wrapping Process

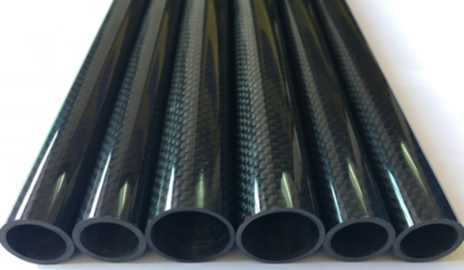

Introduction: Ultra-light composite tubes are structures created by wrapping pre-impregnated composite fabrics—such as carbon fibers or glass fibers—around a mandrel. The fabric layers are typically oriented in different directions to optimize strength and stiffness. In this process, the mechanical properties of the tube are adjusted by aligning the fibers in each layer in various directions, such as axial, hoop, and ±45 degrees. This unique flexibility allows for the optimization of strength, stiffness, and other performance characteristics. To apply pressure and ensure layer impregnation, the wrapped fabrics are covered with shrinkable plastics. In the final stage, the tube is cured in a thermal oven, resulting in a lightweight and strong cylindrical structure.