Pultrusion

Pultrusion

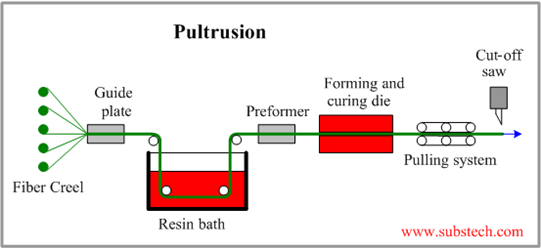

Introduction: Pultrusion is a continuous manufacturing process used to produce composite profiles with constant cross-sectional shapes, such as rods, tubes, channels, and angles. This method is widely used in various industries due to its efficiency in producing composite materials that are high-strength, lightweight, and resistant to corrosion. Pultrusion involves pulling reinforcing fibers through a resin bath, followed by a shaping die and a heated die, to form a cured composite profile with desirable mechanical properties.

MARKETS

- Wind Turbine Industry

- Marine

- Building/Construction

- Industrial

- Transportation

- Other composite application

MARKEt

- Marine

- Building/Construction

- Industrial

- Transportation

- Other composite application

MARKETS

- Wind Turbine Industry

- Marine

- Building/Construction

- Industrial

© Gurit Services AG, Zurich