Filament Winding

Filament Winding

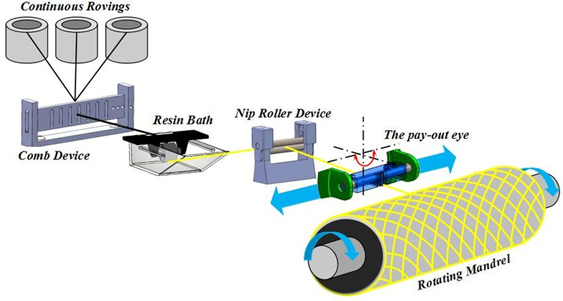

Introduction: Filament winding is a process in which continuous strands or tapes of various materials such as glass fibers, carbon fibers, or aramid are regularly and pre-arranged, wound around a rotating mandrel after being impregnated with resin, and then cured. Once the resin hardens, the mandrel is removed, resulting in a final product that is a high-strength hollow structure. Filament winding is commonly used in industries such as aerospace, automotive, marine, and energy for producing lightweight, high-strength, and corrosion-resistant parts such as pressure vessels, rocket motor casings, pipes, and structural composites.