Vacuum Bag Molding

Vacuum Bag Molding

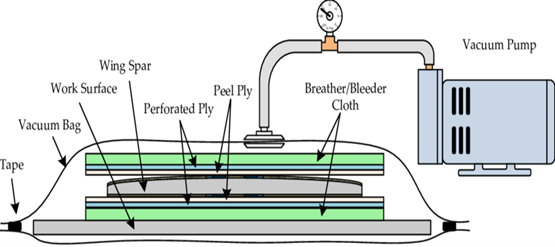

Introduction: Vacuum bagging is a widely used technique in composite manufacturing for creating high-quality, lightweight parts with excellent surface finish and suitable mechanical properties. This method involves applying vacuum pressure to a composite layer, consisting of reinforcing materials and resin, inside a sealed bag to remove trapped air and excess resin. The vacuum bagging process can be performed in two different ways: 1- Hand lay-up vacuum bagging, where the composite is impregnated manually using ambient curing resins, and 2- Only vacuum bag prepreg cure, where the pre-impregnated composite is cured at high temperature in a vacuum bag. Vacuum bagging is commonly used in industries such as aerospace, automotive, marine, and wind energy to produce a wide range of composite components.